Knowledge and skills

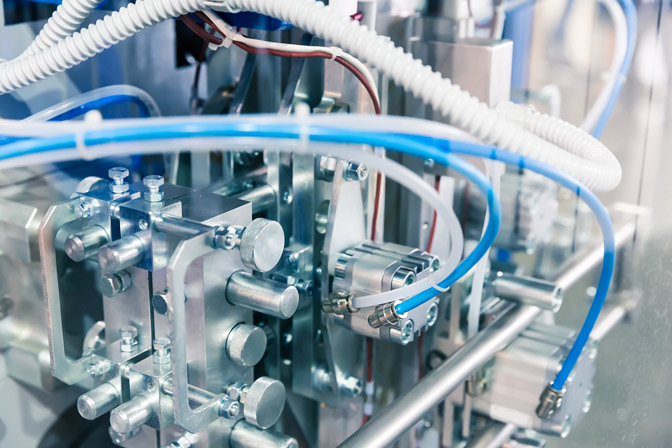

Cable harnesses are a product that is indispensable in many areas of the broadly understood modern technology market. The main purpose of cable harnesses is to connect the component parts that form together a device or system by means of formed cable harnesses with connectors fitted at the ends. The growing interest in this solution in terms of its technical aspects is influenced by the development of this branch of the economy. In recent years, the number of signals that need to be transmitted between devices has increased. It is also important to act in accordance with applicable standards and to underline the issue of safety. Therefore, it is necessary to meet the requirements for electromagnetic compatibility as well as ensure the non-flammability and high quality of insulation – this is why it is worth choosing us! At the Cordify Group, we focus on technology and highly qualified employees.

Qualified staff

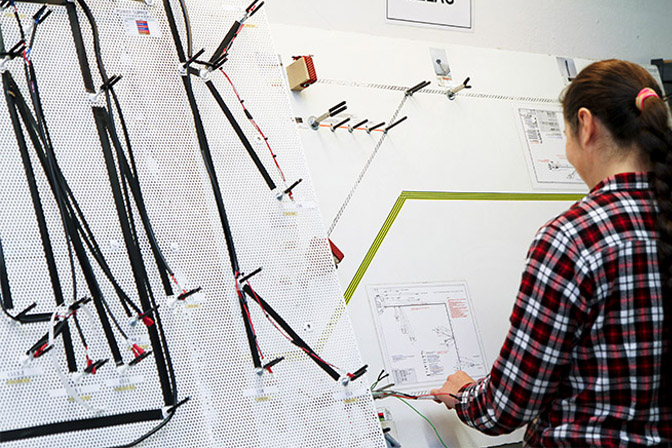

In order to be able to professionally and efficiently solve even the most complex project for our Customer, it is vital to select a team of people who are suitably qualified and eager to work. Due to the fact that our company has managed to gather a lot of trained and motivated employees, we want to emphasise that our cooperation with you does not begin at the start of series production, but much earlier. We support our Customers already at the stage of preliminary talks, design discussions and first prototypes – by offering our experience and knowledge. At the next stage, i.e. during production, we use modern machinery, which also includes tools developed by our specialists. This makes it possible to produce cable harnesses of varying complexity. Through the combination of all these elements, we can guarantee the repeatability and reliability of production as well as an individual approach to the implementation of specific projects.

The machinery created by us includes:

- connector crimping presses,

- dedicated applicators,

- precision insulation stripping machines (for both partial and complete stripping),

- printing machines,

- multi-conductor cable processing equipment,

- automatic cutting and stripping machines,

- machines for cutting PVC sheaths and pipes,

- pneumatic presses for special applications.

Trust in our experience

Do you have any questions or doubts? Contact us by phone or e-mail.

How does cooperation with us look like?

01

The first contact – the handover of the prototype and documentation

02

Establishing technical details – a dedicated consultant

03

Preparation of design samples with documentation

04

Qualitative and functional assessment at the customer's premises

05

Setting deadlines and schedules

06

Long-term cooperation