Flexibly

Production of electrical cable harnesses

We manufacture cable harnesses compliant with the requirements of the IPC/WHMA-A-620 standard

It defines the appropriate selection of materials, tools, methods and tests in order to ensure stable and reliable production of cable harnesses.

We are experts in the field of production and design of cable harnesses, and we have been helping our customers with creating reliable machines and devices for more than a decade. We are proud that our harnesses can be found in various places in Europe and around the world.

Whether it is an agricultural machine covered in dirt and dust, a laboratory device in sterile conditions, or buses in the hustle and bustle of European cities – regardless of this, they are connected by one thing – cable harnesses manufactured by the Cordify Group.

Discover the benefits of cooperation with the Cordify Group

Time

For many of you, contact with the Customer, efficient operation and quick response to changes are the key factors that determine which company you will establish cooperation with. That is why we constantly improve all stages of cooperation with our Customers. Our capacity fot immediate action and our Change Management, which is undergoing constant improvement, allow us to rapidly implement changes or new cable harness designs. We follow the principle that our products belong to the particularly necessary category – therefore, efficient operation means their quick development.

Peace of mind and security

The process approach confirmed by the ISO9001 DEKRA certificate, appropriate production methods and tools, supporting systems and work according to the IPC/WHMA-A-620 standard guarantee the quality and reliability of the wires and cables we offer.

Comprehensiveness

Many years of our experience in the industry and our meticulously built team will make your project smoothly transition from the prototype stage to series production. We are able to increase production capacity both by delivering finished products, but also by pre-assembling electrical system components. The production of cable harnesses is therefore smooth and uninterrupted, which means that the project will be carried out from A to Z – just as planned.

Cost optimisation

Ensuring the profitability of our Customers has always been our priority. By gathering knowledge and working with people from various industries, we have learned that each order is completely different and requires an individual approach. Competitive prices, qualified staff and specialised machinery make it possible to optimise, and consequently, adjust and reduce operating costs. Therefore, the choice of outsourcing in terms of production carried out by the Cordify Group allows for considerable savings.

How does cooperation with us look like?

Cooperation with our company is based on several stages, which enable electrical harnesses and cable sets to be created via analytics, i.e. through the analysis of needs and expectations. The above-mentioned stages include:

01

The first contact – the handover of the prototype and documentation

02

Establishing technical details – a dedicated consultant

03

Preparation of design samples with documentation

04

Qualitative and functional assessment at the customer’s premises

05

Setting deadlines and schedules

06

Long-term cooperation

The Cordify Group in numbers

90%

As many as 90% of our Customers officially

declare their willingness to maintain

and expand their current cooperation

with the Cordify Group, which makes us

extremely happy!

Manufacture of electrical

cable harnesses

Nowadays, it would be difficult to find a machine or device that does not require power or control signals. Most of the equipment that we use on a daily basis is equipped with wiring harnesses for power and control. Here at the Cordify Group, we have been focused on the production of cable harnesses since 2010! Our acquired knowledge and many years of experience allow us to not only serve the domestic market, but also cooperate with foreign Customers. We carry out all orders efficiently, reliably and at the same time professionally, maintaining the highest quality standards.

Cables and wires

The cable harnesses we offer are manufactured in accordance with the requirements of the IPC/WHMA-A-620 industry standard, therefore we ensure that cutting, joining, assembly and final inspection of cable harnesses takes place in a properly prepared technical environment.

Products – production of harnesses for industry

We are experts in the field of production and design of cable harnesses. Throughout a period of over a decade, we have established cooperation with companies representing various industries. Thanks to this, our offer includes:

- bespoke electrical harnesses, e.g. for agriculture or construction,

- cable harnesses for the transport and communication sector,

- electrical harnesses for the lighting sector.

Apart from that, we specialise in the production of custom harnesses used in laboratories and medicine. The production of such wiring is based on class III of the IPC 610/620 standard. Because of this, you can be sure that all our products are made precisely and reliably, so that they will remain efficient and functional for as long as possible.

Production processes – how are electrical harnesses made?

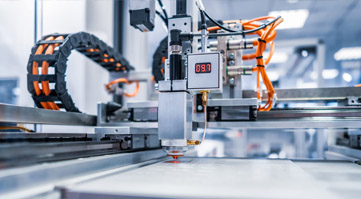

The production of electrical harnesses is a process supervised by specialists who operate modern devices for processing wires and cables – for many different applications. The highest quality of our products is achieved through professional technical equipment, qualified staff, as well as experience and cooperation with the Customer.

Electrical harnesses are manufactured in an extensive machine park, which is controlled by trained operators. Production is carried out with machines such as:

- crimping presses,

- automatic machines for cutting and stripping cables and wires,

- dedicated applicators for a given connector,

- multifunctional soldering stations.

Due to the use of appropriate equipment and the involvement of our employees, the production process is efficient and repeatable.